Let's start with what Production Pro isn't. Production Pro is not an ERP or MRP software package. It does not track inventory or give you fancy charts about your shop's performance. There are dozens of good packages that you can purchase that will do those things. However, virtually all of them increase the labor burden on shop employees with a great deal of data entry. Production Pro is a tool for the shop floor.

Production Pro was designed with a set of clear and specific goals:

- Enable shop floor employees to reduce the overall time it takes to make a product

- Reduce costly defects and errors and increase overall quality

- Preserve and secure company intellectual property

- Reduce the impact of employee turnover and overall training time

- Enable shop floor personnel accountability

- Produce critical documentation for audits

- Increase overall process visibility

- Be easy to implement and not require expensive infrastructure

- Accomplish all of the above without providing an excessive data entry burden

Production Pro Documents Your Manufacturing Processes

You can document every aspect of all of your manufacturing processes with Production Pro.

Manage Part Information

Production Pro puts all information about a specific part or product at your shop employee's fingertips. From just basic descriptions, material and finished part locations, specific run information, drawings, deviation reports, related CNC machine files, part notes - you can add as much as your employees need to facilitate fast setups.

Parts can easily be duplicated, so jobs that are nearly identical can be reproduced in a snap.

Operation/Process Information

Record every detail of an individual process. Production Pro has specific templates for milling and turning operations, inspections, and a generic template that allows you to easily document every process. Easily create and sort setup and process steps, add tools and accessories, process notes and more. Operations can easily be duplicated within a part or copied from one part to another, significantly reducing data entry time for similar jobs.

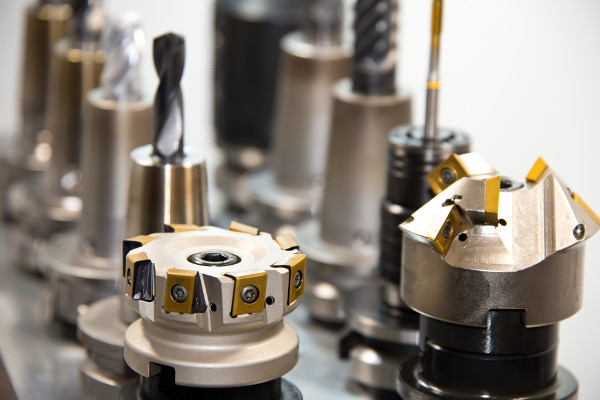

Tools

Sorting out what tools are needed for an operation can take time, especially if this is a job you've not run before. With Production Pro, employees immediately see what tools are needed for an operation. Once you've created a tool and its setup, you can mark it as a favorite if it is one you'll use frequently. This helps ensure repeatability - parts can be produced exactly the same way, every time.